Last week I traveled to Louisville, QC, which is about 75 miles northeast of Montreal and also happens to be where Recipes for Disaster and Expect Resistance are printed. Ostensibly I went up there to do a press check for ER, but perhaps more important to me was that after seven years of publishing books, I was finally able to see one being printed, in person, for the first time. The short version is it was super-awesome and the 5 (of 7) signatures of ER I saw get printed looked amazing.

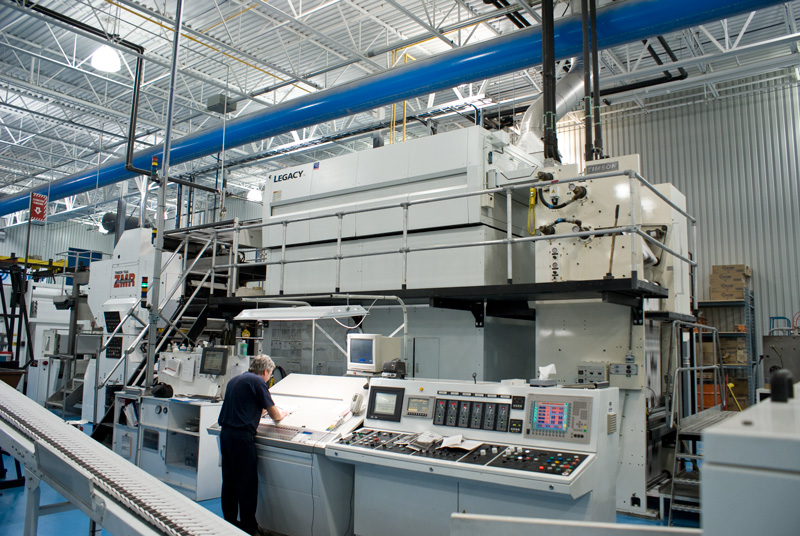

The book is printed on a special heat-set web offset press made just for printing books; this particular press was created a couple years ago just for this printing plant. It’s a multi-million dollar piece of equipment, and is operated primarily by one person, from the console in the photo. He can adjust registration, ink coverage and speed all from the console—it’s pretty amazing and radically different from every other web-press I’ve seen. From left to right: a) the paper is fed from giant rolls into the press, b) it goes through two printing heads (the section in the photo with ‘ZMA’ on it), each printing on the front and back of the paper simultaneously, c) it then goes through a heater unit that dries the ink (the section in the photo with ‘Legacy’ on it), and d) it moves onto a machine that cuts, collates and folds it—more on that part below.

Expect Resistance is 344 pages long and is made up of seven signatures (4x56 + 2x48 + 1x24) that are printed one at a time and then combined together to form the whole book. Each signature requires four plates, as pictured above, one for each color on each side. The plates pictured above are made of flexible aluminum and are wrapped around a metal cylinder on the press; they make a 56-page signature, with 28 pages per side. The plate on top in the photo is the red-ink plate, with a black-ink plate underneath it, and so on.

This is a back view of one of the printing head units, which is closed during operation. This unit is where the red-ink plates for the front and back are housed with an identical unit above it that does the black-ink. During operation, both units are closed and all control and manipulation is done from the console. Both colors and sides are printed inline in one run through the press.

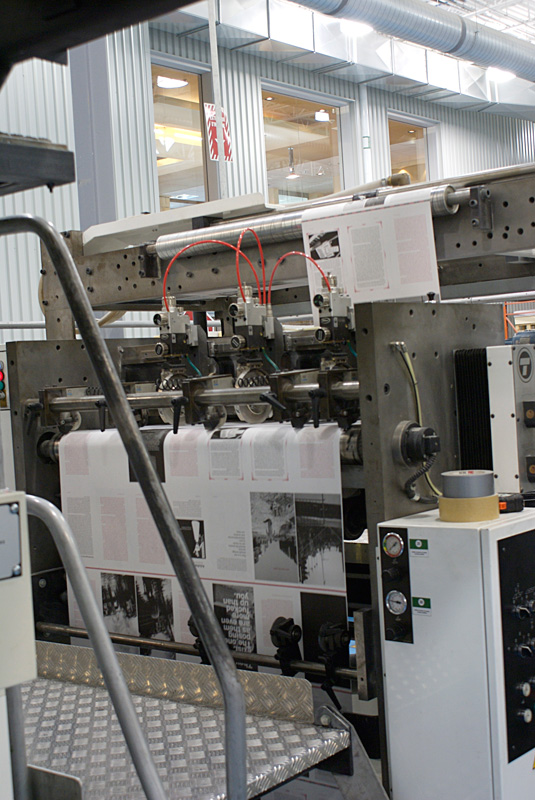

After the paper has been printed and the ink dried in the heating unit, it then moves to the trimmer and collator. If you look closely you can see the giant sheet being trimmed using rotary blades—the sheet in the foreground contains all 56 pages, but the sheet in the background has been trimmed and now only has a 24 page section. The other sections have been trimmed and directed out of sight.

Detail.

Here you can see the three sections being collated together after trimming. One 24-page section on top, an 8-page section in the middle, and a 24-page section on the bottom. After being combined, they are trimmed again and folded together, completing a 56-page signature.

These are the finished signatures coming out of the press. From a roll of paper to these finished signatures, the entire process is done inline and mechanically. Even crazier is, once the press is set-up and adjustments have been made to get the perfect amounts of ink on the plates and fine-tuning the image registration, the printer can print 13,000 signatures an hour—yes,that is 217 a minute or more than three-and-a-half per second.

The finished signatures are collected and strapped between two pieces of wood, prepared for collating and binding. Once all seven signatures are printed they are fed into another giant machine which automatically collates them, saws off the spine for a rough edge, lines the newly-rough spine with PUR glue and binds the signatures together into to the cover. Sadly, I had to leave before that part of the process, so I have no photos.

While they prep the signature and make all the adjustments to get the text and images perfectly rendered on the paper, they have to run the press, albeit at a very slow speed. These ‘make-ready’ signatures are rejected and piled in the recycling bin—here they are, looking so sad, devastated to have been so close to immortality, but not close enough.

Interesting tidbit: This plant and this very printing press were used to print all the North American copies of the last two Harry Potter books. We thought that was pretty awesome.

Small reward for crazy people who read this far down: ~~The books are totally finished and are shipping out from the plant tomorrow. We plan to have the book web page up and accepting orders by Friday night. The books will ship out no later than Tuesday the 4th.~~ Due to unbelievable absurdities, the books have been delayed a week—we now plan to have the book web page up and accepting orders by Friday the 7th. The books will ship out no later than Tuesday the 11th.